Smokeless tobacco or SLT is used by nearly 365 million people in 140 countries, with India sharing a large burden within Southeast Asia. SLT is either chewed or sucked as zarda, khaini, gutkha or snuffed nasally in the form of naswar and bajar. Despite the magnitude of the problem, global efforts to control the use of SLT trail behind the progress made in curbing cigarette consumption.

SLT consumption is widely known to be a leading cause of head and neck cancers. Out of the 4,200 chemicals that have been identified in SLT products, more than 30 have been classified as known human carcinogens by the World Health Organization’s (WHO) International Agency for Research on Cancer (IARC). The two most dangerous tobacco-specific nitrosamines (TSNAs) found in these products, N’-Nitrosonornicotine (NNN) and nicotine-derived nitrosamine ketone (NNK), are listed as Group 1 human carcinogens by the IARC.

With the intent of identifying chemicals that pose significant health risks, scientists across the world are working toward defining the chemical composition of tobacco, studying the cultivation, curing, processing, and storage of tobacco and how SLT is produced. They have observed that during cultivation, active germs or microbes such as bacteria, viruses, and fungi from the environment and residues of agricultural chemicals (pesticides, fungicides, herbicides) get deposited on tobacco leaves. After harvesting, unwashed tobacco leaves are dried by fire, air, flue, or sun-curing. The chemical residues and microorganisms remain on tobacco leaf surfaces and are present even in the final product. During the manufacturing process, these microbes help metabolise reducing sugars present in the leaves, which decreases the harshness and improves the flavour of tobacco.

When tobacco turns bad

The harms associated with the presence of microbes in SLT products weren’t addressed until recently. These microbes directly enter the oral cavity and can form biofilms, secrete endotoxins/mycotoxins, and produce proinflammatory-like molecules, leading to several oral diseases. Scientific evidence suggests that by causing chronic inflammation or producing carcinogenic metabolites like TSNAs, these microbes can contribute to cancer formation. A recent study indicated that microbial communities in tobacco impact the TSNA level of SLT products. Upon consumption of the product, TSNAs get absorbed in the body and get metabolised into several reactive compounds, which induce tumours by damaging the normal DNA and RNA, leading to oral, oesophagal, pancreatic, and lung cancers.

TSNAs aren’t present in freshly harvested tobacco but are actually formed during the curing process when microbes convert nitrate to nitrite. Nitrite, in turn, reacts with tobacco alkaloids such as nicotine and nornicotine, forming carcinogenic TSNAs. Factors such as humidity, airflow, temperature, and the fuel used for heating the tobacco also influence the level of carcinogenic TSNAs in the product. The manufacturing of khaini, zarda, gutkha, toombak, and snuff involves various steps, including fermentation, ageing, and long-term storage of tobacco. Carcinogenic TSNAs are generated during all these processes.

A recent review covered the series of TSNA-related biochemical and chemical transformations from tobacco cultivation to cancer initiation. SLT manufacturing is often carried out in an environment with limited oxygen levels, increased microbial activity, and rapid chemical changes, all of which contribute to the generation of carcinogenic TSNAs.

The review article provided an in-depth understanding of the compounds, their precursors, the microbial and chemical mechanisms that contribute to their formation in SLT, and their mutagenicity that leads to cancer. It also suggested measures for tobacco manufacturers to lower TSNA levels in SLT products — washing the soil and newly harvested tobacco with pressurised steam can remove microbes. Newer technologies, such as electron beam irradiation and pasteurisation of tobacco early on, can eliminate microbes during processing. Refrigeration of SLT products inhibits microbial growth and activity and retards reactions that form TSNAs.

Also read: Areca Nut isn’t a harmless sweet ‘supari’. Govt must regulate it like tobacco

What can be fixed — and where

There are grassroots methods to control the production of carcinogenic TSNAs in SLT products. And these can be implemented at different stages of production and processing.

Curing techniques

Studies have shown that flue and fire-curing result in higher TSNA levels in the final product as compared to air-curing. High temperatures during curing enhance biochemical reactions, therefore, air or sun-curing can be viable options to reduce nitrosamine content in SLT products.

Using another bacteria

The best approach is to identify and target the specific groups of bacteria that contribute to the production of TSNAs. Staphylococcus and corynebacterium, present in tobacco leaves or within the manufacturing environment, actively induce the formation of NNN and NNK. Some fungi and yeast populations, too, allow the conversion of nicotine into nornicotine, thereby increasing NNN and NNK content in tobacco. A solution is to add non-nitrite-forming bacteria. Moreover, nitrite-scavenging chemicals such as ascorbic acid, tocopherol, and polyphenols, can help too.

Pasteurisation during tobacco processing

Modifications to processing and storage conditions—especially pasteurisation in the case of Swedish snus—to lower microbial levels can decrease levels of toxicants in SLT products. Swedish snus products are processed using heat treatment to reduce or eliminate microorganisms, resulting in much lower levels of TSNAs than products that are fermented during processing, including moist and dry snuff.

Addition of humectants & additives

Humectants such as glycerol and propylene glycol can be added to tobacco products to facilitate the processing of the cured tobacco leaf and retain moisture with lower water activity to thwart microbial growth and increase shelf life. These additives block the microbes’ canonical capabilities to convert nitrate to nitrite efficiently.

Cleaning practices

Industry experts suggest that washing tobacco leaves at the time of harvest can reduce or eliminate microbes, soil particles, and agricultural chemicals. Cleaning or sterilising equipment and fermentation vessels between fermentation batches during manufacturing can greatly reduce the growth of microbes in SLT products.

Packaging & storage condition

Humidity and high temperature play significant roles in the generation of TSNAs when SLT products are stored. Studies have shown a correlation between moisture content and bacterial colonisation and suggested that moist samples had the highest bacterial contamination, both in terms of number and diversity. The factors combine with alkaline pH and high moisture levels in the SLT product.

Storing leaves

Tobacco leaves are often stored in farms, and later, with tobacco product manufacturers for three to 18 months for processing. High water content, along with insufficient air, supports microorganism growth in them.

Finished SLT product

Stepanov and coworkers have been constantly monitoring the levels of TSNAs and nicotine in various SLT Products in the United States market over the last decade. They found that storing wet or high-moisture SLT products in large containers at 37 degrees Celsius or above can markedly increase TSNA formation. This could be due to insufficient air movement, which leads to bacterial growth. The pack or pouch size of the product also plays an important role in the production of NNN and NNK — large tin packs have higher moisture content than ‘slim pack’ versions. Snus tobacco products are manufactured and packed by using a technology that not only retains colour, flavour, and fragrance but also controls bacterial growth even after long storage. However, products such as Chaini Khaini, which is widely marketed in India and explicitly claimed to be a safe alternative to other tobacco products, contain remarkably high levels of TSNAs.

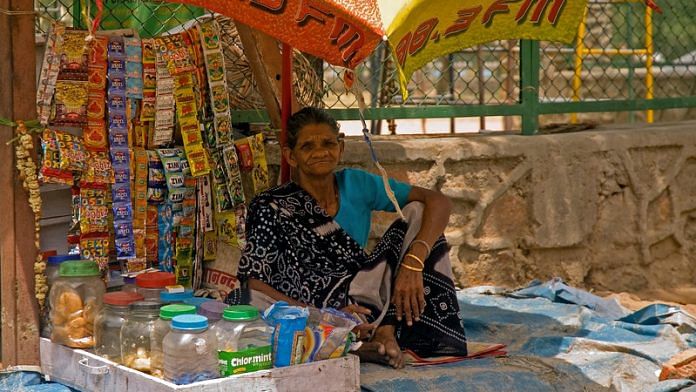

Scientific evidence says that the ‘ageing’ of SLT products can be slowed down by keeping the product refrigerated below 8 degrees Celsius. Unfortunately, in India, most of the SLT products are stored and sold on roadside stalls and small shops in cities where there’s high humidity and heat conditions.

Also read: Great Indian Paan caught in health vs livelihood battle. Ban hurting magahi betel, areca nut

Road ahead

Monitoring and controlling microbial contamination early on while processing SLT products can greatly reduce nitrosamine formation. It is high time for the government to come up with appropriate policies to standardise the manufacturing and storage of SLT products in India.

No tobacco product can be classified as “safe” and nicotine addiction is very difficult to break. By no means do we mean to promote tobacco use, however, the health risks associated with consuming SLT products can be greatly reduced if active regulatory measures are taken. A report by the US Food and Drug Administration indicates that reducing levels of carcinogenic nitrosamines in SLT products could lower the risk of developing cancer and thus enhance the quality of life by reducing mortality, morbidity, and medical expenditures due to cancer.

Alpana K Gupta is currently a research consultant at the Centre for Health, Innovation and Policy. Prof. Ravi Mehrotra is the Director of Indian Cancer Genome Atlas & Founder of the Centre for Health, Innovation and Policy Foundation at Noida. He tweets @ravimehro. Views are personal.

(Edited by Humra Laeeq)