You might think that the car you buy is made by a manufacturer—such as Maruti Suzuki or Tata Motors—but manufacturers only design and assemble the vehicles. Whether it’s a passenger car or a motorcycle, all vehicles are just an amalgam of parts made by suppliers across the world. And India has a vibrant automotive component industry that clocked a turnover of $56.5 billion in 2021-22.

With sales of cars and commercial vehicles booming over the past months, the industry expects to grow by 15 per cent in the financial year beginning 1 April 2023.

But at a summit to celebrate technological innovation and increased indigenisation (or ‘Atmanirbharta’ in government-speak) hosted by the Automotive Components Manufacturers Association (ACMA), it became apparent that the industry faces significant headwinds. For example, the industry exported $19 billion and imported $18.3 billion worth of components in 2021-22. It gave India a $700 million export surplus in automotive components. This year, however, things are a bit different. For the first nine months, exports and imports were at $15.1 billion each.

Also read: Delhi-Mumbai Expressway is impressive but Indians’ driving lanes apart

Surplus in imports

There is a reason India is importing more components—regulatory issues around both emissions and safety. The imported components are the ones that Indian companies do not have the skill set to make. An industry executive gave the example of tire pressure monitoring systems (TPMS), which is a system that warns you about the loss of pressure on a tire. Right now, all but entry-level hatchbacks have a TPMS system. For someone who drives a lot, they can be useful. But each car requires one sensor for each tyre and given that close to four million cars will be sold in India by the end of March 2023, that is a lot of imported sensors.

But even where India has managed to gain manufacturing competencies, especially before a regulatory change, there are problems. Enter airbags. From mid-2023, every car sold in India will need to have six airbags. Ever since the government made them mandatory, manufacturers have added their manufacturing capacity in India. According to an ACMA executive, India makes between 36-40 million airbag modules every year. But only 40 per cent of the system is indigenised. Most importantly, the high-strength fabric used to make the airbag is imported.

Other changes in emission norms such as Real Driving Efficiency (RDE), which will kick in on April 1, present another problem for the industry. While it is certain that TPMS and airbags will be made in India, RDE norms have meant that small diesel engines on passenger cars are on the verge of extinction. And this is just the start, increased levels of technology and the shift towards electric vehicles present more challenges.

“We don’t make enough electronic components in India, and as an industry, we have to work towards this,” says Sunjay Kapur, chairman of Sona Comstar and president of ACMA.

“The PLI (production-linked incentive) scheme that will encourage the manufacturing of semiconductors in India should help the industry, but we do not yet know what sort of semiconductors they will make. However, the automotive industry has become a major consumer of semiconductors and I’m sure that domestic manufacturing of semiconductors will address the segment,” he adds.

Also read: Mercedes-Benz to Skoda—the driving experience is fundamentally changing. Over to software

Bumpy road ahead

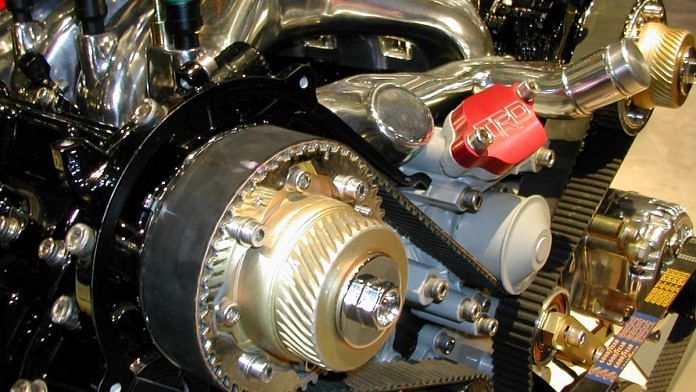

As previous Dashboard columns have noted, software components and not mechanical or hardware ones are becoming vital for new vehicles. Kapur says that a couple of software companies have already signed up for ACMA membership and more will be admitted going forward.

“But most importantly, we are meeting the OEMs (vehicle manufacturers) on technology issues to understand their future requirements and direction that the industry is taking,” Kapur adds.

The industry is in the middle of a complicated multi-level traffic interchange going in multiple directions. Kapur says that the internal combustion engine is going nowhere for now. He believes that as manufacturers in Europe and North America move towards electrification, work on internal combustion engines will shift to countries like India offering the industry some short-to-medium-term opportunities.

But he agrees that there is a shift towards electrification in India as well, particularly in two- and three-wheeler segments. There is also a shift on ethanol-blended petrol and potentially Hydrogen. “It is an exciting time, but it is our job as an industry association to educate our members of the dramatic changes taking place, especially if we are to take advantage of the ‘China+1’ sourcing strategy of global automotive companies,” Kapur says.

The Indian automotive components industry has made many stock market champions over the years, and some companies have built significant export businesses as well. But vehicle manufacturers are noticing that their buyers want more features and gadgets. And the industry, while not on the back foot and growing bigger every year, is grappling with some serious existential issues.

Kapur and his fellow ACMA members do say that government incentives and the growing domestic demand hold out an opportunity for companies. But as the spurt in imports has shown this year, the road ahead for automotive component manufacturing in India will be bumpy.

@kushanmitra is an automotive journalist based in New Delhi. Views are personal.

(Edited by Ratan Priya)