New Delhi: In what is being termed as beginning of a new era of the India-US partnership, American firm General Electric Thursday announced signing of an MoU with India’s state-run Hindustan Aeronautics Limited (HAL) to jointly produce fighter jet engines for the Indian Air Force (IAF) with “significant amount of transfer of technology and work being done indigenously”.

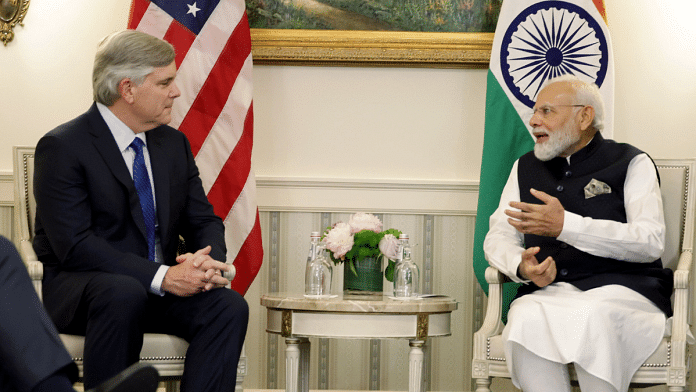

The deal, which could eventually end India’s quest since the 1960s to manufacture its own jet engine, is one of the big highlights of Prime Minister Narendra Modi’s ongoing state visit to the US.

The agreement includes the potential joint production of GE Aerospace’s F414 engines in India, and GE Aerospace continues to work with the US government to receive the necessary export authorisation for this, the American firm said in a statement.

Sources in the defence and security establishment said that an actual deal will be signed once both sides thrash out the nitty gritties and the deal goes through the US Congress, the permission of which will be required.

The clearance from the US Congress is a 30-day process.

Once cleared, HAL will carry out the work at its Engine Division facility in Bengaluru and the co-production will not be through a joint venture, the sources said.

Jet engine technology is seen as the holy grail when it comes to aviation. While a number of countries, including India, make their own fighter aircraft, the technology of engine manufacturing has been aced by only a select few.

Asked about how much of transfer of technology (ToT) is involved given the fact that some reports have put the value at 80 per cent, sources refused to get into the details saying that everything is still under discussion and finer details are yet to be firmed up.

“The level of ToT and the engine manufacturing work done in India will be very significant. This is not an assembly, but joint production that will take place,” a source said.

The sources underlined that the jet engine partnership heralds the beginning of a new era of India-US relationship.

As reported by ThePrint, ToT for jet engines was the main thrust of National Security Advisor (NSA) Ajit Doval’s talks with his American counterpart Jack Sullivan in February when they also operationalised the US-India Initiative on Critical and Emerging Technologies (iCET).

The F414 engine, which is an afterburning turbofan engine in the 22,000 pound (98 KN) thrust class of engines, was shortlisted by India in 2010 to power the Mark II version of the indigenous Light Combat Aircraft (LCA) Tejas, which currently comes with GE F404 engine.

Once the engine production starts in the country, the F414 engine will power all future fighter jets including the Tejas Mk II and the indigenous Twin Engine Deck Based Fighter (TEDBF) for the Indian Navy.

The Boeing Super Hornets and the Swedish fighter Gripen, both of which are on offer to the Indian military, are among those aircraft that run on this engine.

India is also working on a 5th generation plus fighter known as the Advanced Medium Combat Aircraft (AMCA), which could be powered through a newer version of a higher thrust class.

Sources said that the road taken for partnership could eventually lead to joint design, development, and manufacture of more powerful engines. As per the schedule plan, the process will involve first making components for the engines in phases before actually moving to the full step up which will take at least a decade, the sources said.

Also Read: Inside story of why India’s military worked to push mega US drone deal

Quest for jet engine

India has been pursuing the jet engine technology for decades, and it was shaped by the problems faced by the country’s first indigenous fighter HF-24 Marut.

The aircraft was originally meant to be powered by the Bristol Orpheus 12 engine, but was fitted with the less-powerful Bristol Orpheus 703 after the North Atlantic Treaty Organisation (NATO) project to develop the engine collapsed.

The Gas Turbine Research Establishment (GTRE) in Bengaluru eventually produced a more powerful version of Orpheus 703 with afterburners, significantly enhancing the engine’s power, but was found to be unsuitable for the Marut’s airframe.

And the quest began again in 1983 when the government sanctioned work on the LCA project following which feasibility studies in India and abroad revealed that while there was no entirely suitable engine available worldwide, the Rolls-Royce RB-1989 and GE F404-F2J, by and large, met the requirement.

Since 1982, the GTRE had been working on the indigenous GTX-37 engine, and pushed for its adoption on the LCA. In December 1986, it proposed the development of the Kaveri engine for which the government then sanctioned Rs 382.86 crore in the following year in March.

While the GTRE developed nine prototypes of Kaveri engines, as well as four core engines that undertook 3,217 hours of engine testing, including in Russia, they failed to meet the required parameters to power a fighter.

Instead of a so-called ‘wet thrust’ of 81 kN — the thrust the engine should deliver when the fighter needs maximum power — the Kaveri generated only 70.4 kN.

GE entered India through LCA programme

It was in 1986 that GE began working with the Aeronautical Development Agency and the HAL to support the development of LCA with F404 engines. Subsequently, GE Aerospace’s F404 and F414 have been part of development and production programmes of LCA Mk1 and Mk2.

In total, 75 F404 engines have been delivered and another 99 are on order for LCA Mk1A. Eight F414 engines have been delivered as part of an ongoing development program for LCA Mk2, the American company said in the statement.

Friday’s agreement will advance GE Aerospace’s earlier commitment to build 99 engines for the IAF as part of the LCA Mk2 programme. “It puts the company in a strong position to create a family of products in India, including the F404 engine that currently powers the LCA Mk1 and LCA Mk1A aircraft and GE Aerospace’s selection for the prototype development, testing and certification of the AMCA programme with our F414-INS6 engine,” the statement said.

It further said that GE will continue to collaborate with the Indian government on the AMCA Mk2 engine programme.

(Edited by Tony Rai)

Also Read: Vikramaditya back in action after 2.5 yrs, Navy to get 2 more Romeo helicopters to deploy on board