New Delhi: At the fourth edition of World Food India, the spotlight largely fell on the sprawling stalls of giants like Hindustan Unilever and Nestlé, distributing samples of their latest products. Yet tucked away in Hall 14 of Delhi’s Bharat Mandapam, a modest booth drew curiosity for a different reason. Its product is being used in what many call the next frontier in food technology: lab-grown meat.

And it is one of the Indian government’s newest priorities — to look for alternative protein sources at a time when vegetarianism is finding a new and unapologetic resurgence.

“We had a client in Goa who wanted us to make cultivated crab meat, because that is what the demand is in the region,” said Siddharth Manvati, co-founder of Clear Meat, which manufactures serums to grow cells in a controlled environment. “We are on a mission to empower the entire food industry to bring in cultivated meat.”

Unlike traditional meat, which requires the slaughter of animals, cultivated meat is produced by growing animal cells outside the body. These cells multiply and form muscle and fat, which are then structured into a chicken breast or fish fillet. This is different from the already widely available plant-based meat, made from ingredients like soy or peas that are processed to taste like meat.

Once limited to science fiction films like Star Trek, cultivated meat is on the brink of hitting restaurant plates and grocery stores. Still a nascent industry, especially in India, a slew of startups, think tanks, and government initiatives have propelled ‘smart proteins’ to the forefront of conversations on sustainable food.

“The government wants India’s bio economy to reach $300 billion by 2030. And ‘smart proteins’, which includes cultivated meat, is one of the six prioritised thematic sectors under the policy,” said Chandana Tekkatte, Head of Science and Technology at the Good Food Institute – India, a think tank that works toward advancing the smart protein industry. She added that the government sees India as an innovation and bio manufacturing hub for smart proteins.

Biokraft Foods, a Mumbai-based startup, has already conducted taste tests and cook–offs using their cultivated chicken breasts as the main ingredient. The Department of Biotechnology (DBT), through its recently launched BioE3 (Biotechnology for Economy, Environment, and Employment) policy, is funding researchers and companies working on animal cell cultivation. And it’s not just chicken that’s on the menu — mutton, pork, and fish cells are also being grown.

The new food era is here. For it to scale, all these pieces — research, innovation, production — need to come together

– Rajesh S Gokhale, Secretary for the Department of Biotechnology

“Our role is to make a convergence of all the activities in this space so that they work together,” said Rajesh S Gokhale, Secretary for the Department of Biotechnology, explaining that his department’s focus is supporting the entire ecosystem. “Startups, large companies, innovation hubs, research institutions — all of these cannot operate separately.”

‘New food era’

Startups working on ‘smart proteins’ are reaping the benefits of the BioE3 policy, launched in August 2024. In April 2025, the Biotechnology Industry Research Assistance Council (BIRAC), a non-profit set up by DBT, called for proposals from companies working on alternative proteins. Neat Meatt, a Hyderabad-based cultivated meat startup, was incubated at BIRAC’s Bio-NEST.

In August 2025, one year after the policy was announced, Minister of Science and Technology Jitendra Singh said the government was working toward the target of $300 billion by 2030, up from $165 billion in 2024. He also announced the launch of the National Biofoundry Network to scale up biomanufacturing, which will also include growing cultivated meat.

“The new food era is here. For it to scale, all these pieces — research, innovation, production — need to come together,” said Rajesh S Gokhale, adding that he sees a tremendous opportunity in this space. “That’s why DBT is focused on funding research labs while BIRAC funds startups and companies. We are trying to do this end to end.”

One of the largest booths at World Food India belonged to the Ministry of Food Processing Industries (MoFPI), the organiser of the event. Marico, ITC, and Britannia all set up shop around the main booth, but MoFPI wasn’t ignoring the smaller, innovative companies working on alternative proteins.

“The understanding we have with MoFPI is that we will provide them with the innovation, and they will help us make it mainstream,” said Manvati, highlighting the MoU signed between Clear Meat and MoFPI at the event. “The government of India is trying to penetrate this idea of sustainability.”

The Clear Meat collaboration will be undertaken through the National Institute of Food Technology Entrepreneurship and Management, Kundli (NIFTEM-K), established under MoFPI in 2012 to support the ecosystem in the food processing sector. GFI India also partnered with NIFTEM-K for a ‘Smart Protein Project’ to stimulate research and innovation on the institute’s campus.

“We have also funded research endeavours at IIT Madras and IIT Bombay to develop serum-free media for chicken and goat cells,” said GFI India’s Chandana Tekkatte.

Also read: Small hotels are the backbone of India’s new sex culture. And this is their daily fight

Trial and error

In August 2025, student chefs from India’s leading hospitality and culinary institutes competed in a cook-off at DY Patil University’s School of Hospitality and Tourism Studies in Mumbai. From tacos to burgers, students prepared elaborate dishes using one key ingredient — cultivated chicken meat.

“Seeing your product being made in 50 or 60 different forms — Konkan, Goan, South Indian — was the real validation for us,” said Kamalnayan Tibrewal, founder of Biokraft Foods, which organised the Great Indian Cultivated Chicken Cook-Off. “The event was a turning point, where we unlocked the chef community.”

As a Marwadi, Tibrewal grew up on a strict vegetarian diet. But eating meat was never a problem for him, it was the way it was sourced that he took issue with. Although the company was officially founded in 2023, Tibrewal credits its roots to his time as a master’s student at the Institute of Chemical Technology (ICT), Mumbai.

“The R&D in this space started in 2015, so we learned from the research and people’s mistakes,” said Tibrewal, adding that between 2021 and 2023, Biokraft was engaged in developing the base formulation. “The secret sauce took two years of research. We designed a formulation that was not just economical, but also scalable in nature.”

The company spent 2024 validating their product in the market through various internal trials, focusing on students at academic institutions in Mumbai and Pune. Creating products for consumers couldn’t be done by just sitting in a lab.

“The feedback showed us where we were lacking and what improvements we needed,” he said, adding that over 250 people across age ranges were surveyed over three phases. “After every phase, we collected data across demographics on the taste and texture of the meat.”

A sticking point that kept coming up during the trials was around the texture. Testers couldn’t gauge the taste of the chicken through the slider burgers and barbecue chicken pieces that were served during the trials. The various sauces and other ingredients were getting in the way.

Tibrewal went back to the drawing board and worked on the texture over the next three months, before launching the company’s first official tasting event in December 2024. Years of research, market validations, and product enhancements finally paid off — the event was well received.

“After completing more than 300 validations, we decided to target the B2B sector whenever we do our commercialisation,” said Tibrewal, adding that the plan now was to sell chicken breasts to hotels and restaurants. “This is why we decided to host the Great Indian Cultivated Chicken Cook-Off — to target chefs.”

Tibrewal is avoiding the consumer market, where entire chickens are purchased to prepare various meals using breasts, legs, and wings. By focusing only on chicken breasts — which takes the company four days to create — Biokraft Foods is targeting the most demanded piece of meat in the hospitality sector.

And he has a pricing strategy in place for when the company enters commercial production. According to Tibrewal, prices vary depending on the region. In Maharashtra, one kg of chicken breast sells for roughly Rs 280. On e-commerce sites like Licious, the price ranges between Rs 400 and Rs 500 per kg.

For our country’s population, the primary criteria to provide a good source of protein is to make the price consistent and affordable

– Saikat Saha, part of the managing committee of the Compound Livestock Feed Manufacturers Association of India (CLFMA)

“Our target pricing is Rs 300-350 per kg. And we also feel this strategy is the correct one to reach end consumers,” he said. “Like when you order palak paneer at a hotel. It’s not just about the paneer, but the whole dish.”

Choosing not to directly target end consumers makes sense in a price–sensitive market like India, where even an increase in the price of milk — the most common domestic source of protein — sees a dip in its demand.

“For our country’s population, the primary criteria to provide a good source of protein is to make the price consistent and affordable,” said Saikat Saha, part of the managing committee of the Compound Livestock Feed Manufacturers Association of India (CLFMA), which represents various sectors in the livestock industry. “This is a challenge for lab-grown meat, which will probably be affordable for people higher up the income ladder.”

Saha doesn’t see the livestock industry being affected by the advances in cultivated meat. To him, most people in India still buy their meat from the wet market — meaning families choose their poultry from butchers and then buy the meat.

“Despite the industry’s effort over the last 10-15 years to promote processed chicken, it still only accounts for 7-8 per cent of the market,” said Saha. “In that segment, if you add a niche product like lab-grown meat, the scope will be limited.”

Also read: Baniya-branded food is finally on the table. Being Bania, Baniya Kitchen, Baneeya Sa

From lab to plate

At a cafe outside the World Food India exhibition, the Good Food Institute India’s Chandana Tekkatte powered up her laptop and explained the science behind cultivated meat. A tissue engineering expert with a background in biotechnology, Tekkatte heads GFI’s science and technology vertical.

“In India, cultivated meat is in its teenage years,” she said, adding that there are around a hundred companies scattered across the world, primarily concentrated in Europe and North America. “India isn’t far behind. We have six companies working in the space.”

These six companies are spread across different stages in the technological value chain — from cell line development and cell culture media to bioprocess design and scaffolding. Each stage plays a part in bringing a cultivated meat dish from lab to plate.

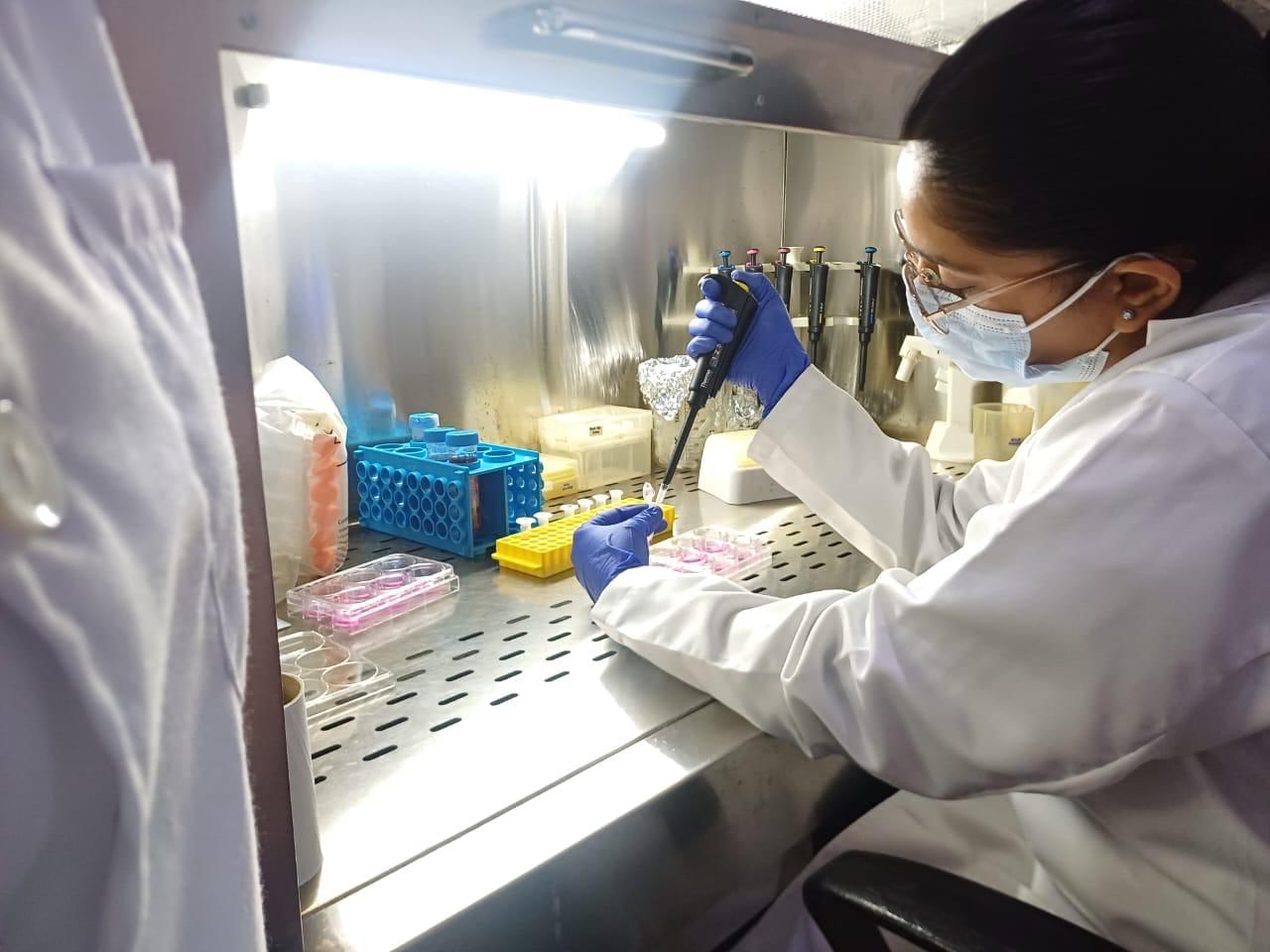

“We know how to grow animal cells outside of the body. We grow cells in labs all the time,” said Tekkatte, explaining that the basic technique of cell culture has been around for more than a century. “But you can’t just grow it in saline or water. You need to add sugars, proteins, and nutrients to make it survive outside the body.”

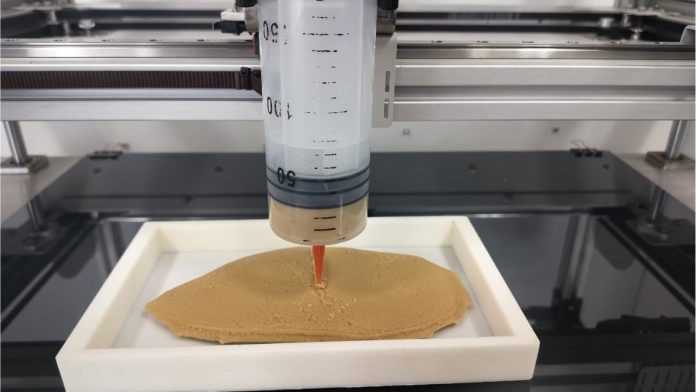

This is where cell culture media comes in, providing ‘food’ for cells to grow outside the body. But to grow cells in large quantities, bioprocess design is used to scale up the process in large reactors.

“And muscle cells can’t just float around. In our body, they bind to connective tissues and fibres, which provide a supportive matrix,” she said, explaining that outside the body, edible scaffolding materials are added so the cells bind to it and gain structure to become muscle-like mass. “Advances in bioprocess technology enable us to grow such cellular biomass on a large scale in bioreactors.”

Biotechnology ends once the tissue masses are formed. That’s when food technology takes over — adding formulations and ingredients to obtain the right texture, structure, and aroma.

But historically, there has been one ethical bottleneck in the process — the use of fetal bovine serum (FBS) as cell culture media to grow cells. FBS is obtained from the blood of cow foetuses during the slaughter of pregnant cows. The applications of FBS extend far beyond cultivated meat — it’s used in vaccine production, biomedical research and academia.

This goes against the promise of ‘cruelty-free’ meat, more so in India where cows are considered sacred in Hindu culture. But research within the cultivated meat industry has yielded breakthroughs.

Clear Meat, a Noida-based startup founded in 2018, has developed a proprietary animal-free growth medium called ClearX9, which replaces FBS in the cell culture process. This solves both the ethical problem of animal slaughter and significantly reduces the cost of FBS, which is entirely imported in India.

“The energy source — the serum used to grow cells — contributes to 60 per cent of the production cost,” said co-founder Manvati, clasping a bottle of ClearX9. “And it takes months on end for FBS to be imported to India, which further delays the production process.”

Manvati views his company as the ‘Intel Inside’ of the alternative protein industry — supplying his product to all cultivated meat companies. Eight cultivated meat companies outside India, including ones in New Zealand and Singapore, now use ClearX9 to grow their own meat. In the last year, Clear Meat sold 250-300 litres of cell growth media to research labs, pharma companies (vaccine production), and hospitals (stem cell therapy).

Regulatory hurdles

But while research and innovation is thriving, regulations haven’t caught up just yet. The Food Safety and Standards Authority of India (FSSAI) — the apex regulator driving food innovation in India — hasn’t approved any cultivated meat product. Currently, these products fall under the ‘Non-Specified Food’ category.

“Cultivated meat is a novel product, which means it doesn’t have a history of consumption,” said Astha Gaur, Senior Policy Specialist – Regulatory at GFI India. “Under the non-specified food regulation, there would be a pre-market approval under the Approval of Non-Specified Food and Food Ingredients Regulations (NSF Regulations 2017) that a company would have to file for.”

Companies would have to make an application, which includes a dossier with safety assessment data that FSSAI would scrutinise and then approve. But Gaur is positive that the regulator is making strides in the right direction, considering the sector is at a very nascent stage, not just in India but globally.

“At the Global Food Regulator Summit, there was a discussion on novel foods and cultivated meat,” said Gaur, adding that it shows how positive the regulator is in India. “So just taking from that note — and I’m being ambitious here — it may take anywhere between 1.5-2 years before we see these products in the market.”

With the foundational pieces in place, a big focus is now on scaling up production through bioreactors. It’s one thing replicating animal cells in a controlled environment, creating proof of concepts, and undertaking taste tests. But producing cultivated meat on a mass scale to feed millions is a very real challenge.

“The high cost and the scale up engineering challenges are still being tackled. In India, we can crack both because we have biotech expertise, cheap equipment, low-cost growth media and enabling policies like BioE3,” said Tekkatte.

She added that most challenges that face the sector are being tackled by India. “International companies are coming to India for our equipment and know-how because we can design and manufacture at much lower costs.”

Biokraft Food’s Kamalnayan Tibrewal is optimistic about the future of both his company and the industry. His plans involve expanding to Southeast Asia instead of the West and not just selling chicken and fish but even pet food. He even views his company as a tech startup, with the aim of licensing their technology and becoming the world’s largest food tech developer.

“We want to control the entire supply chain of cultivated meat—like Domino’s or Pepsi,” he said.

(Edited by Aamaan Alam Khan)