For nearly 70 years, Herbert Squire’s theory has reigned supreme. But Nayanika Majumdar & Mahesh S. Tirumkudulu are set to change that.

Bengaluru: Nozzles and sprays that release a fine mist have found applications the world over, starting from the beauty industry to art to automobile manufacturing to cooking.

But while we have perfected the design of the nozzle — with the ability to adjust for different types of sprays — we still know very little about how mist itself works. What is the physics behind the phenomenon that causes a body of water to break up into minuscule, refreshing droplets of water?

For nearly seven decades, the reigning theory has been that of Herbert Squire, a British aerospace engineer. But a new study conducted by scientists from IIT-Bombay, published earlier this year, has challenged the conclusions of Squire’s theory, and put forth their own about how mist works.

Squire’s theory and what it gets ‘wrong’

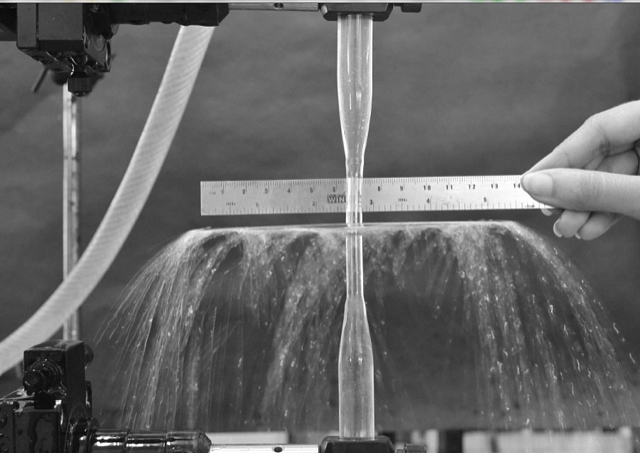

Squire’s theory states that when water is ejected out of a nozzle, it is released in the form of a thin sheet. This can be observed in nozzles of certain industrial kinds, such as a spray fan nozzle.

This thin sheet of liquid flaps up and down due to air, like “a flag that flaps in a strong wind”. This flapping of the sheet causes instability at the ends, breaking it up into millions of tiny droplets of water towards the end of the sheet.

According to Nayanika Majumdar and Mahesh S. Tirumkudulu of IIT-B’s chemical engineering department, who have conducted the aforementioned study, Squire’s theory holds true for the most part, except the crucial bit of how and why the sheet splits into droplets. They state that Squire’s explanation works for uniform sheets of water, but not for sheets produced by a nozzle.

“Frankly, a uniform thickness sheet is an idealisation and all liquid sheets thin as they spread out from the nozzle,” said Majumdar.

A nozzle creates what is called a geometric thinning of the liquid sheet, which in turn causes the flapping, instead of the air molecules. This was built upon an earlier study done with Manjula Paramati, a former student in the lab, and it demonstrated that the flapping occurs irrespective of a surrounding gas, contrary to Squire’s predictions.

Research methodology

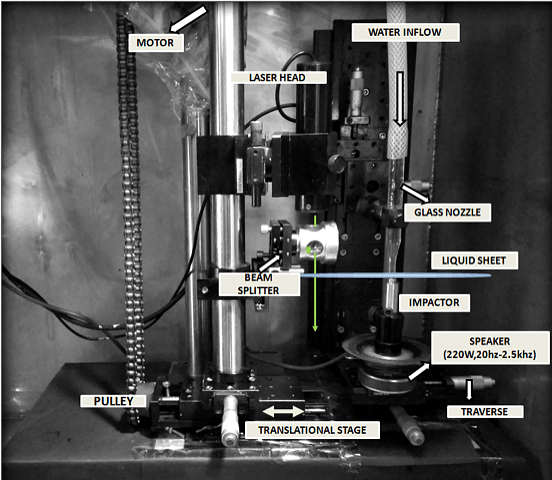

To study these waves and their breaking up — in a process called ‘atomisation’— the researchers followed the method of actually introducing a wave into the sheet of water emanating from the nozzle by giving the source a little jerk.

As a wave travels through a sheet, its amplitude varies according to the thickness of the sheet. When it reaches the thinner portions of the sheet, the height of the wave increases as the flapping intensifies. The team measured this by pointing a small but precise laser at the waves, which hit the liquid and was reflected back on to a screen with marked measurements. The reflection hit the scale in increasing order of height as the wave propagated through the sheet.

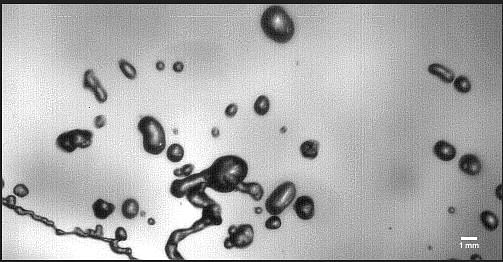

While the height increases in one part — the crest— of the sinusoidal wave, the lower part of the wave — the trough — is at a different pressure due to the air flow around it. This pressure difference between the crest and trough of the same wave causes the two parts to move away from each other, breaking up the sheet.

This observation was made across different environments and air pressures, including in vacuum. The duo concluded that disturbances always exist in all media and in vacuum, and propagate waves through varying thicknesses of sheets. These waves always increase in amplitude as they move away from the nozzle, breaking up the sheet into millions of minuscule droplets.

Observing a sheet of liquid and its ends breaking up into droplets of water is much easier than one would expect. This can be done by just turning on a water faucet and jutting a spoon into the stream, as the video below demonstrates.

For Majumdar and Tirumkudulu, this research has been no cakewalk. Having worked on it for over six years, Majumdar says the team struggled with both the complex mathematics involved in understanding and simulating the flapping of the liquid sheets.

It was also particularly challenging to conceptualise the theory of how the sheet thinned. Of course, the experimental setup involving vacuum came with its own challenges too. Their new paper further reinforces the new thinning theory they had put forth all the way back in 2013 as well.

Potential benefits

The team’s findings have potential benefits for the manufacturing of nozzles, primarily. Currently, nozzles tend to spray out liquids at top speeds to combat the flow of air around and stick to the desired size of droplets.

However, with Majumdar and Tirumkudulu’s research, the exact droplet size can be predicted beforehand by controlling the sources of waves and disturbances at the nozzle itself. By varying the amplitude and frequency of disturbances, the same nozzle can produce different droplet sizes.

This could hone the design of nozzles, which can then be capable of generating sprays of various droplet sizes. The findings could potentially have massive impact in industrial type nozzles.

“Nozzles are used in various application such as in combustion (jet engines, gas turbines, LPG burners), coatings, agriculture, milk powder processing, ink jet printing, medical applications, paper pulp processing, and more,” said Majumdar.

“We anticipate that these results will not only lead to more accurate predictions of the final drop size distribution but also lead to more efficient design of atomisers (nozzles).

“Future work envisages determination of droplet ejection frequencies, estimation of droplet diameters, and development of strategies based on model predictions for droplet size optimisation, which should lead to better designs of nozzles for control on the final drop-size distribution.”

How cone Einstein predicted that…didn’t Hawkins give theory of blackholes?

Einstein came up with General Relativity, which stated that when light passes near a body with a great gravitational force, it will get stretched out. He didn’t specifically say black holes, which is what Hawkins came up with.