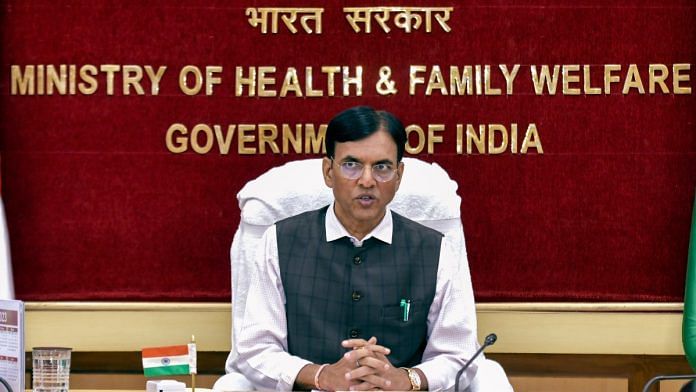

New Delhi: Union Health Minister Mansukh Mandaviya Wednesday announced that all drugmakers with an annual turnover of over Rs 250 crore will have to mandatorily adopt good manufacturing practices (GMP) within six months. Companies with a turnover of less than Rs 250 crore will be given a year to complete the process, he added.

“This timeline for completion of GMP norms begins August 1,” Mandaviya said at a press briefing.

The Union minister said that Schedule M of the Drugs and Cosmetics Act has not been implemented properly by the majority of the drugmakers, but “that is going to change now”. He added that those who do not follow the timelines will be penalised according to the provisions of the law after two reviews are conducted — after six months and one year.

Schedule M of the Drugs and Cosmetics Act, 1940, deals with GMP for pharmaceutical manufacturing units, including specific requirements pertaining to premises, plant and equipment. GMP are mandatory standards which build and bring quality into product by way of control on materials, methods, machines, processes, personnel and facility or environment etc.

GMP were first incorporated in Schedule M in 1988. The norms were last amended in 2018.

There are around 10,500 manufacturing units in the country, of which around 8,500 fall under micro, small and medium level enterprises, or MSMEs.

India is a major exporter of medicines to low- and middle-income countries which require GMP certification from the World Health Organisation (WHO), said a statement issued by the health ministry. “We have around 2,000 units in the MSME category in the country having WHO GMP certification.”

Also Read: Govt tightens screws on pharma MSMEs, stresses on good manufacturing practices, self-regulation

‘Poor documentation, absence of self-assessment’

Pharmaceutical manufacturing and the quality domain have developed significantly in the last 15-20 years, the ministry said in its statement. “Our understanding of the domain has increased because of development in pharmaceutical and manufacturing sciences…Linkage between manufacturing and product quality and interdependence between the two has been established.”

Observations from ongoing risk-based inspections further reiterated the need to have a relook at the current GMP regulations and quality management systems being followed by pharmaceutical manufacturers, it further said.

According to the statement, drug regulators — as part of a drive to crack down on faulty drugmakers — inspected 162 units and 14 public testing labs over the last six months.

Major issues detected during these inspections included poor documentation, lack of process and analytical validations, absence of self-assessment, absence of quality failure investigation, absence of internal product quality review, absence of testing of incoming raw material, infrastructural deficiency to avoid cross-contamination, absence of professionally qualified employees, faulty design of manufacturing and testing areas, the ministry said.

“Based on these factors and to keep pace with fast changing manufacturing and quality domain, there was a necessity to revisit and revise the principles and concept of GMP mentioned in current Schedule M. This would bring our GMP recommendations and compliance expectations at par with global standards, especially to those of WHO, and ensure production of globally acceptable quality of drug,” read the statement.

Accordingly, on the basis of discussion and recommendation of the Drug Technical Advisory Committee, a draft notification was issued in 2018 to upgrade and synchronise Schedule M of the Act with international standards.

Some of the major changes that will happen with the introduction of a revised Schedule M to support upgradation of the units are — introduction of Pharmaceutical Quality System (PQS), Quality Risk Management (QRM), Product Quality Review (PQR), qualification and validation of equipment, change control management, self-inspection and quality audit team, suppliers audit and approval, stability studies as per recommended climate condition, validation of GMP related computerised system, specific requirements for manufacturing of hazardous products, biological products, radiopharmaceutical and phytopharmaceuticals.

This will address most of the deficiencies related to documentation, failure investigation and technically qualified personnel with the right person doing the right job, the health ministry said.

“It will support development of robust quality management system in the company, thereby enabling production of globally acceptable quality medicine. Better quality management will help manufacturers grow their business nationally and internationally, which is a huge opportunity for Indian pharmaceutical business,” read the ministry statement.

(Edited by Gitanjali Das)

Also Read: Jan Vishwas Bill doesn’t dilute punitive provisions of Drugs & Cosmetics Act, says health ministry