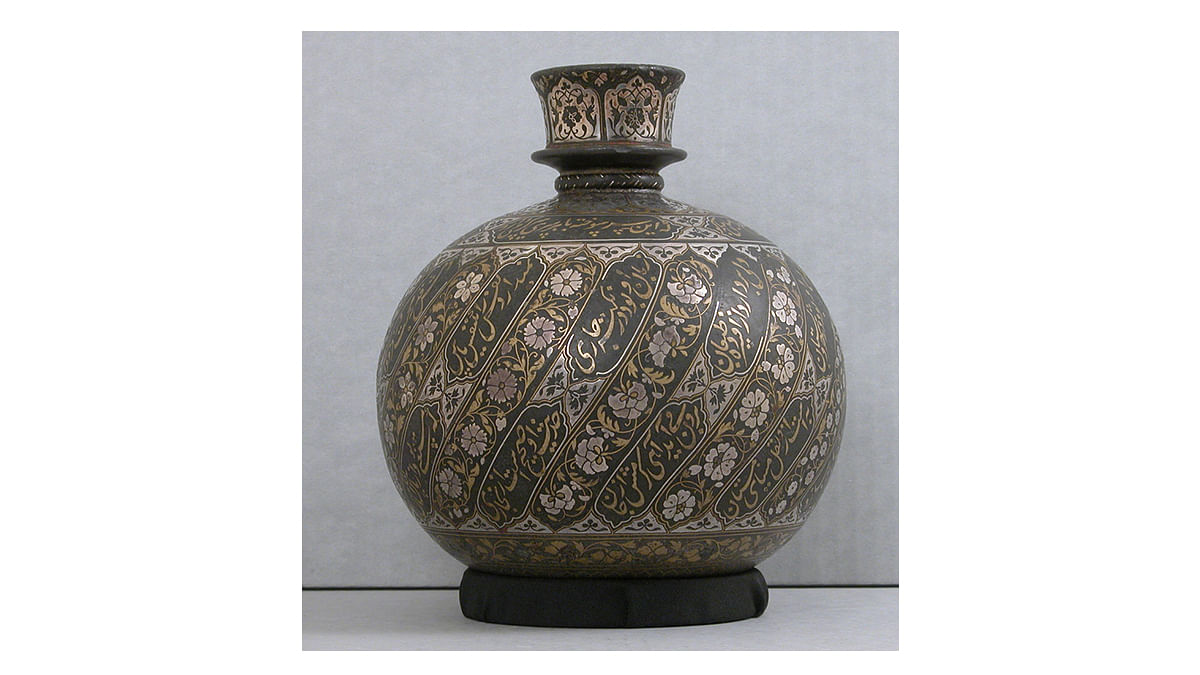

A technique of damascening, Bidriware features metallic inlay against a darker base metal alloy layer. The technique derives its name from the town of Bidar, in present-day Karnataka, India, once the capital of the Bahmani Sultanate, whose rulers are believed to have patronised the art form. Bidar remains one of the chief centres of Bidriware production in the country, alongside Hyderabad in present-day Telangana.

The earliest evidence of a Bidriware object comes from a Deccani painting dated to c. 1625, in which an officer of African descent is seen smoking a hookah made in the Bidri technique. It is likely that the technique was practised in the Deccan region from much earlier, though its origins cannot be precisely traced.

The technique is believed to have been introduced to the subcontinent by Persian and Syrian artisans who migrated to the Deccan region under the patronage of the Bahmani sultans. Some of the artisans are believed to have accompanied the Sufi saint Muin-ud-Din Chisti (1141–1236) to the northern parts of the subcontinent. Knowledge of the technique was then carried into Bijapur (now Vijayapura) in Karnataka.

The production of Bidriware in Bidar is believed to have begun during the reign of Alauddin Ahmad Bahmani II (r. 1436–58), who encouraged artisans from Bijapur to settle in the capital. The technique flourished in Bidar and Hyderabad between the sixteenth and nineteenth century and regularly appeared in Deccan paintings from the seventeenth century onwards. Bidriware from the region was also exported to the Mughal court, Rajput courts of Rajasthan and Maratha kingdoms. By the late eighteenth century, the technique had spread to the Muslim courts of Purnia (in present-day Bihar) and Murshidabad (in present-day Bengal), and by the nineteenth century, to Lucknow (in present-day Uttar Pradesh). Bidriware was practised in these regions till the twentieth century. The art form was also extensively patronised by the Asaf Jahi Dynasty that ruled over the Hyderabad State between the eighteenth and twentieth centuries.

There was a marked change in the types of products made by Bidriware artisans during the colonial period. Earlier, the technique was used to embellish objects such as hookah base, abkhora or katora (bowl), aftaba (ewer), pandan or khasdan (box for betel leaves), ugaldan (spittoon), palang pae (cot legs), shamadan (candelabra), uddan (incense burner), gulab pash (rosewater sprinkler), alam (Shia standard) and cups with Quranic or Shia inscriptions in Arabic script. In the colonial period, the technique began to be applied to large flower vases and basins, mirror and picture frames, chairs, buttons, walking sticks, cigar boxes and inkstands. Bidriware was exhibited at colonial exhibitions, including the Great Exhibition of 1851, the Exposition Universelle in 1855 and the Delhi Durbar of 1903.

In terms of their design, the Bidri objects in the first half of the seventeenth century were inspired by Mughal decorative arts, Persian and Islamic metalware and Chinese porcelain. The Chinese influence on design was also strongly visible in Purnia, where it may have arrived from neighbouring regions such as Nepal and Sikkim. Popular patterns of seventeenth-century Bidriware were floral arabesques and floral motifs, inspired by Mughal art and Deccani manuscript painting in terms of visual style. In the eighteenth century, a popular motif, also derived from Mughal art, was the poppy flower, which was used extensively. In Lucknow, the double-fish insignia of the Nawabs of Awadh was a common motif. Purnia — where some Chinese motifs were also used in Bidriware — had two categories of Bidriware according to the finish — gharki bidri (superior) and karna bidri (inferior). By the mid-nineteenth century, as the quality and use of the poppy motif declined, the kothmir (coriander) leaf motif became popular, and its variations were used until the twentieth century. Towards the end of the twentieth century, the range of motifs included zodiac signs and designs inspired by the mural paintings of the Ajanta Caves, as well as displaying European influences. At the time of writing, artisans have expanded their repertoire to work on purely decorative objects, such as wall plaques.

Also read: The protector Goddess of Buddhism—Marichi and her many symbols of strength, knowledge

There are three primary stages of production of Bidriware, each of which requires a specialised group of artisans. The first stage involves moulding and casting the base object, which requires zinc, copper, red clay, resin, castor oil, sangjeera (white stone powder) and coal. The body of the object is made of a metal alloy — primarily zinc, with small quantities of copper, tin and other metals — and cast in a mould that is held within an iron frame, known as darza. To make the mould, a template object is pressed into finely sifted clay, and the resulting mould is dusted with sangjeera to keep it free from any clay residue. The molten alloy is then cast into the frame. For hollow objects such as vases, the object can be cast in two pieces and soldered at a later stage. Once cast, it is levelled and smoothed using a lathe and files.

The second stage — engraving and inlaying — uses beeswax, copper sulphate, silver, gold and sandpaper. Silver remains the material of choice for inlay work, though brass was used in Deccan Bidriware until the eighteenth century. Silver bars are beaten into sheets or made into wires at a jeweller’s workshop. The metal is further thinned by the Bidri artisans. The surface of the object is then blackened with a solution of copper sulphate to allow the artisan to engrave a pattern using chisels and a hammer.

Different Bidriware production centres use different techniques of inlaying; for example, in the Deccan region and eastern India, the tarkashi (inlay of metallic wires), tehnishan (inlay of metallic sheets over a larger area) and zarnishan (low-relief inlaying) techniques are used. A distinctive inlay style, called zarbuland (high-relief inlaying), was developed in Lucknow. In the zarbuland technique, the silver is inlaid over a lead pad and is then incised with motifs or gold overlay, leading to a high-relief effect. Other inlay techniques include aftabi or mehtabi — where the inlay is done over the entire surface of the object and cut according to a pattern — and Ganga–Yamuna style — where gold and silver are used side-by-side for inlays, though this is now taken to mean an inlay of two or more metals.

Once the object has been smoothed after the inlaying stage, it is treated with a solution of clay that contains saltpetre, sal ammoniac, sodium chloride and other chemicals. Clay from the Bidar Fort or the ruins of old buildings in the area is preferred, as it is believed to contain saltpetre. This step gives the base metal alloy a black colour. Following this, the object is polished with groundnut oil and charcoal.

The Bidriware industry is facing considerable challenges despite interventions by cooperative societies and governmental and non-governmental agencies to boost the craft. The challenges include high cost of and access to raw materials, particularly silver and clay with saltpetre. Artisans are also poorly remunerated. Faced with these issues, Bidriware artisans have switched to using tarkashi and screen printing designs in order to cut down on production time and labour costs. They are also apprehensive about the proliferation of counterfeit Bidriware items.

Bidriware received a Geographical Indication tag in 2008. In Bidar, national award-winning artisans continue to garner commissions.

This article is taken from the MAP Academy‘s Encyclopedia of Art with permission.

The MAP Academy is a non-profit, open-access educational platform committed to building equitable resources for the study of art histories from South Asia. Through its freely available digital offerings—Encyclopedia of Art, Online Courses, and Stories—it encourages knowledge-building and engagement with the visual arts of the region.