Kanpur: Moments before the New Delhi-Lucknow Shatabdi Express halts at the Kanpur Central railway station, an in-train announcement welcomes passengers to “India’s leather capital”. On a recent journey, this leads one of the passengers, who owns a Kanpur tannery, to quip, “The day is not far when the Shatabdi announcement will welcome people to India’s ‘pan masala’ capital.”

Kanpur’s famed leather industry — valued at Rs 9,000 crore and employer of lakhs — has found itself under siege since the Kumbh Mela in Allahabad this January.

Shut down by the Yogi Adityanath government over the untreated effluents the factories pump into the Ganga, they are yet to be reopened two months after the grand festival concluded on 4 March.

Some tannery owners told ThePrint that only 21 of the bigger tanneries were currently functioning. They alleged that these were the biggest players in Kanpur’s leather industry and had far too much clout to be permanently shut down.

UP Minister of Industrial Development Satish Mahana, who hails from Kanpur, denied the allegation.

“We are pro-industry and we want to promote Kanpur’s leather industry. We have only banned tanneries that directly release their water into the Ganga and haven’t put primary treatment plans in their units,” he said. “We will arrive at a solution together.”

Meanwhile, as one drives through Kanpur, hoardings seem to announce the advent of a new industry: Pan masala, with locals saying that a new brand has been popping up in the sector every few weeks.

Also read: Ayodhya, ghar wapsi, gau raksha: How BJP, RSS & affiliates used Kumbh Mela to push Hindutva

Kumbh and the leather industry

The central Uttar Pradesh city has 400 sanctioned leather tannery units, according to the Kanpur Small Tanners Association, of which 230 are functional.

The leather industry accounts for Rs 6,000 crore of exports and another Rs 3,000 crore of domestic supplies annually.

The tanneries employ about two lakh people directly while another eight lakh find employment in the city’s leather industry as a whole.

This entire ecosystem was brought to a standstill this year, when the state’s pollution watchdog, Uttar Pradesh Pollution Control Board (UPPCB), forced most of the tanneries to temporarily shut down on 8 January, just before the Kumbh Mela was to begin.

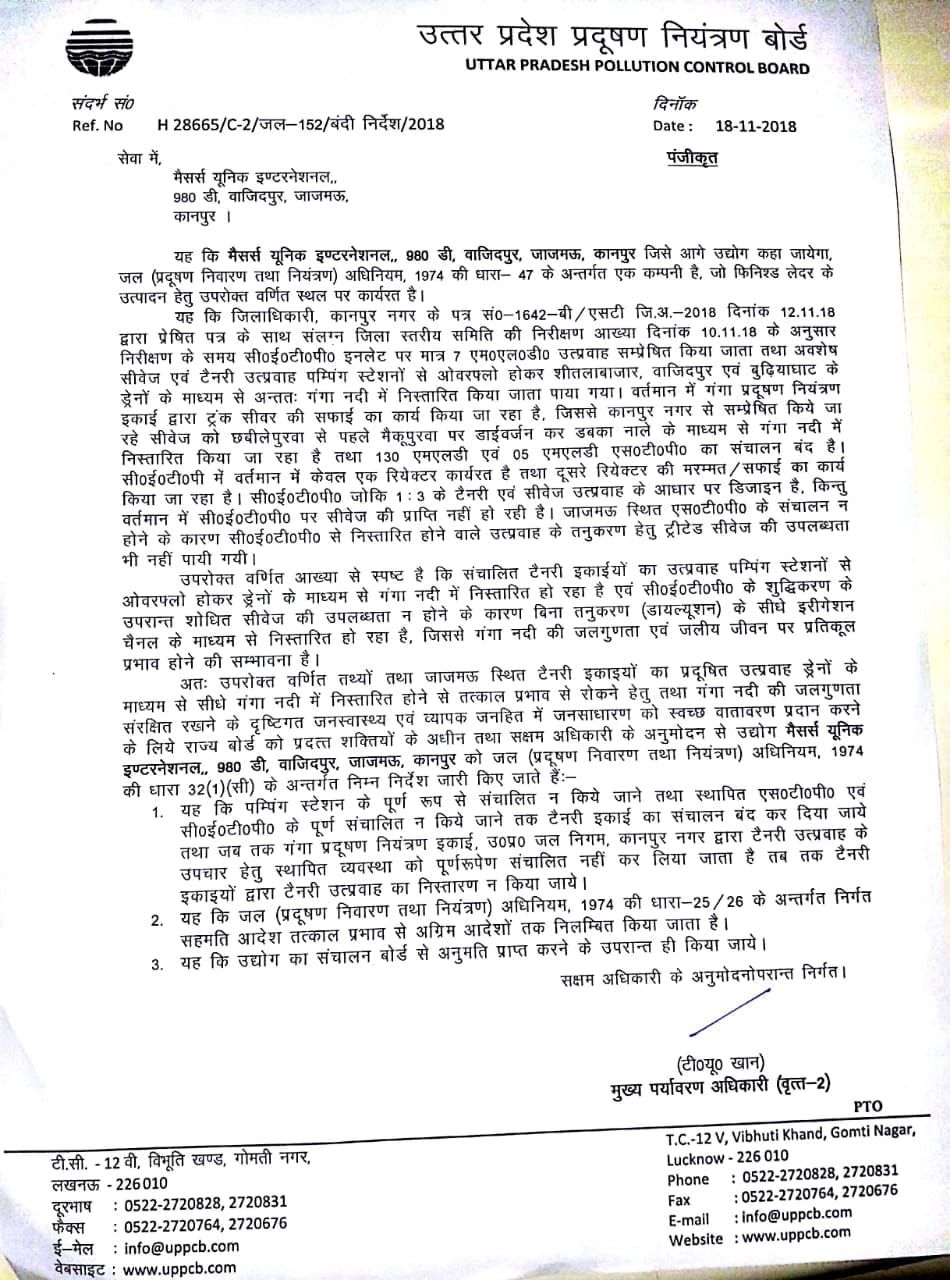

An initial order had called for the industries to be shut down on 18 November 2018, saying the Ganga needed to be cleaned up for the hundreds of thousands of devotees who would take a dip in the river during the Kumbh Mela.

However, tannery owners told ThePrint that after they lobbied with the state authorities, the ban was temporarily lifted on 15 December.

“No processing has taken place since 5 January,” Naushad Alam, partner at Shalimar Tanning Industries, told ThePrint. “The entire leather industry in Kanpur has been brought to a halt.”

The shutdown has had a catastrophic effect on the prices of rawhide, the main component of leather production: They have crashed to Rs 700 apiece from about Rs 2,000 in just the past few months.

As most rawhide is now being directed to Kolkata, the price there has fallen as well, to Rs 500 apiece, owing to a supply glut. Meanwhile, the leather exports from Kanpur fell by an average of 20.6 per cent between November 2018 and January 2019.

Kanpur’s tanneries fostered several other sectors, such as footwear and saddlery. The blanket ban on leather processing has, as a result, also negatively impacted these businesses.

“We used to extensively buy leather from the local tanneries, now our main channels of supply have effectively shut down,” said S.K. Dhawan, owner of a saddler business, Global Export.

The predecessors

The closure has been unprecedented for the tannery industry, with players saying that the previous administration understood the significance of the Ganga bath as well, but found mutually-agreeable suggestions for Kumbh.

Under the Akhilesh Yadav-led Samajwadi Party government, a roster system was followed during the Kumbh Mela.

Several tannery owners told ThePrint that they were allowed to produce leather for two days and then told to halt production for three. The rationale is that it takes three days for Ganga’s water to reach from Kanpur to Allahabad. Hence, tanneries would close down three days before the days outlined as particularly auspicious for the “nahaan (holy bath)”.

The Yogi Adityanath-led BJP government replaced that system with a harsh blanket ban.

A delegation representing Kanpur’s tanneries went to meet Adityanath. Naiyer Jamal, partner at Makhdoom Tanning Industries, a local player, told ThePrint that the chief minister said he had “seen” the impact of the tanneries on the Ganga.

“During my visit to Kanpur, I saw the black effluent from tanneries being released into Ganga,” Jamal quoted Adityanath as having said.

When the delegation said the effluents were not from their factories, Adityanath replied, “I surveyed Jajmau in a helicopter and saw the black effluent from tanneries fall into the Ganga.”

Akhilesh Yadav of the SP raised the plight of the industry at a recent rally, saying, “Yogi government’s policies are helping Pakistan.”

Yadav was referring to how the shutting down of tanneries in Kanpur is reportedly compelling buyers to meet their demands from Pakistan and Bangladesh. Tannery owners corroborate this claim.

Asked when the factories were likely to reopen, government officials in Kanpur told ThePrint that it would have to wait until after the election, which ends 23 May.

Who is responsible for polluting the Ganga?

Tannery players say their waste-water is treated twice before it flows into the Ganga — first at their plants, and then at the Common Effluent Treatment Plant (CEPT), which is operated by the UP Jal Nigam.

The CEPT has a capacity of 36 million litres per day (MLD), of which 9 MLD is dedicated to effluents from the tanneries.

When this plant was set up in 1992 with the help of Dutch expertise and investments, tannery owners paid 17.5 per cent of the Rs 21 crore project. They continue to bear 50 per cent of the plant’s running costs to this day.

However, this plant has not been upgraded to keep up with the industry’s growth. The CEPT was originally built to treat effluents from 175 tanneries, but their number has nearly doubled since. This means that the treatment plant is simply not equipped to clean all the waste-water generated.

“Another treatment plant dedicated to only tannery-related effluents has been sanctioned by the central government. But until it’s built and operationalised, the problem will continue,” said Naiyer Jamal.

Minister Mahana said a change in inputs had led to the tanneries releasing more toxic water than they did before. “Earlier, the tanneries used vegetable tan for processing, which caused lesser pollution. This has now been replaced with the chemical chrome, which is highly polluting,” he added.

“Ganga’s water is not just about religious faith,” he said, “it is also the lifeline for a lot of people.”

Also read: This Kanpur village drinks neon green water & lives near a toxic waste dump as big as CP

The look of a deindustrialised city

The pollution closure was just the latest knock for an industry that has been reeling over the past few years.

After its thriving textile industry downed shutters in the 1970s, Kanpur became a hub of medium and small enterprises (MSME). However, demonetisation and the Goods and Services Tax (GST) alone have reportedly forced 100 tanneries to shut down since November 2016, besides having devastating effects on other MSME players as well.

Until GST was implemented, manufacturers with an annual turnover of up to Rs 1.5 crore were exempt from paying excise duty. GST came into effect by subsuming a range of other taxes, including excise duty, and the turnover threshold was brought down to Rs 20 lakh — which meant several other manufacturers were now liable to pay tax.

This threshold has since been increased to Rs 40 lakh (this threshold varies between states) following widespread consternation among small businesses.

However, the tax led to a massive reallocation effect that left several smaller businesses struggling.

Meanwhile, the GST has led to a huge windfall for pan masala manufacturers. Before GST was implemented, industry players in Kanpur said all pan masala manufacturers had to pay a daily excise duty of Rs 1 lakh. Excise duty varies on the basis of the price of a product and the size of its manufacturing unit.

With GST, this cost has come down, making it easier for new players to enter the business. As a consequence, a new pan masala brand is launched every few weeks, say residents.

Do no harm. That Hippocratic injunction also holds true for governments, which have so much influence over our lives. One of the first things the Bisht government did was to completely disrupt UP’s meat trade, to everyone’s detriment, most of all the Muslim community. The menace of stray cattle. No one expects all campaign promises – Z A Bhutto wanted Pakistani workers to drive to office / factory in a Mercedes – but please don’t snatch away what little people have. –