Lucknow: Spread over 50 acres in the Uttar Pradesh Defence Industrial Corridor, India’s PTC Industries is setting up four manufacturing plants focused purely on titanium and superalloy production to meet not just India’s defence demand but global need.

Titanium and superalloys, which are nickel and cobalt-based, are used for defence manufacturing. Superalloys are used for high temperature scenarios, like in aero engines.

The company, which is investing close to Rs 1,000 crore, has already started supplying titanium parts to BAE Systems for its M-777 ultra-lightweight howitzers that India also uses.

Other top global vendors like Israeli Aerospace Industries (IAI), Safran and Dassault Aviation have already signed long-term contracts with the Indian firm.

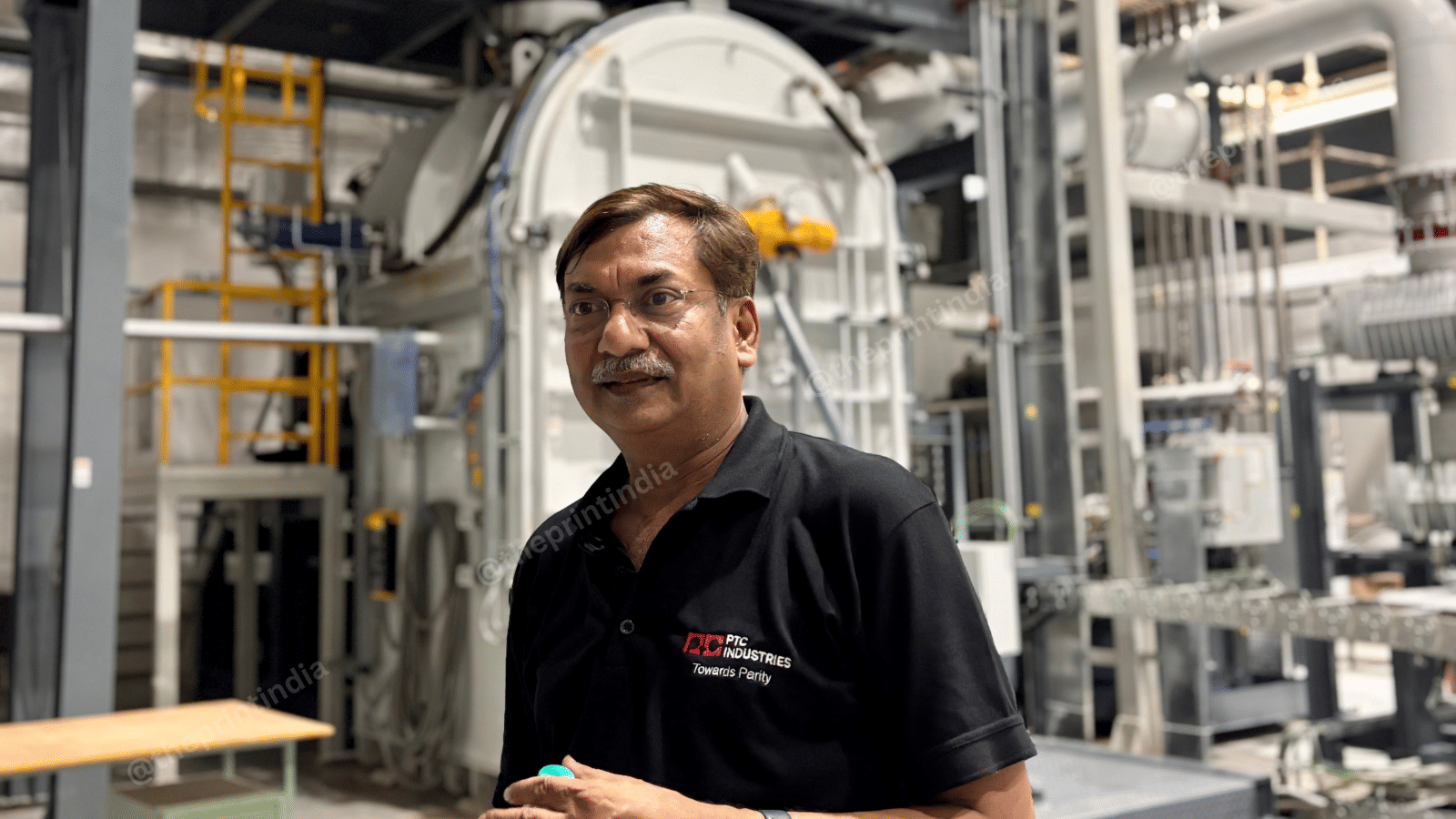

“We believe in the motto of Make in India for India and the world. The deal with Safran is not just for defence engines but their civil ones. We have signed a contract with Dassault Aviation. All the titanium casting that goes on Rafale (aircraft) will one day be ours,” Sachin Agarwal, Chairman and Managing Director of PTC Industries, told ThePrint.

Explaining why foreign companies are coming to him, he said that titanium is made globally by a limited number of countries.

“If you leave China, out of the close to 170,000 tonnes of titanium manufacturing in the world, Russia produces 60,000-70,000 tonnes, which is 30-40 percent of global numbers,” he explained.

Sachin added that the global supply chain has been hit due to the Russia-Ukraine war and the desire to pull away from China.

“All of Europe and American companies want titanium and superalloys from non-China and non-Russia countries. And this is where India comes into play. It is a god given opportunity. And that is why we are doing it. Nobody in India is doing this and we are the first ones to do so and it holds a lot of scope globally,” Alok Agarwal, Director, Technical and Quality, at the company, told ThePrint.

He said that, currently, MIDHANI, a key defence PSU based in Hyderabad, makes titanium but the supply is less.

“We are the only private company in India which makes titanium and superalloys material. MIDHANI does a small quantity compared to what we have planned and are going to do,” Alok added.

Explaining further, he said that one of the four PTC plants being set up is a metals factory which is manufacturing titanium and superalloys.

“Then there is a large forging unit which is going to forge the parts, and another facility for making titanium and superalloy parts, and then there is a machining factory coming up which will manufacture parts,” he said.

Sachin said that he and his team brainstormed seven-eight years ago and assessed the areas in defence and aerospace that the company should enter.

“We did gap study. We found that there is a certain technological and capability gap. Most of these are primarily related to materials capability and certain core manufacturing capability. Our objective was to put the country on a par when it comes to materials itself.”

“This is our strategic material technology complex where we are covering all material and technological gaps we found, primarily two critical sectors: titanium alloy and superalloy related,” he told ThePrint.

Emphasising on criticality, Sachin said that India has a dream to manufacture its own aero engines. “But we can’t make them until we have the capability to make our own superalloys and the components that go into the aero engine,” he added.

PTC Industries has acquired a British company that manufactures aero engine blades and other parts. “The idea is to manufacture everything from base material to high-end aero engine parts,” he said.

(Edited by Nida Fatima Siddiqui)

Also read: Nod for additional Scorpene submarines still awaited, Navy & Mazagon Dockyard Ltd in limbo