Kanpur: The Centre for Mechatronics in the department of mechanical engineering at IIT-Kanpur is just another nondescript set of rooms — much like the numerous others that flank its corridors. But the moment you enter it, there is a small four-wheeled rover — not much larger than an average dog — placed on some sand and rocks on the concrete floor.

“Oh, this? This is the Chandrayaan rover,” says Ashish Dutta, Dean of Digital Infrastructure and Automation. He brushes off further questions about the rover, calling it a very old development, mildly amused at the interest it piques.

For Dutta, the rover is passe. “Our work with this is done, it’s up to the Indian Space Research Organisation whether they’ll send the same rover up again on the next mission,” he says. He’d rather talk about a 3D printed robotic arm that could revolutionise the rehabilitation of stroke patients.

Like Dutta’s department, there are several others at IIT Kanpur that are working on next-gen inventions — including robots that scour gas pipelines, security tags that are safer than QR codes, and smartwatches for the visually impaired. Some of these are awaiting trials, while some are ready for commercial usage. As ThePrint reported last month, there’s even an artificial heart in development.

Behind the inventions is a common desire.

“Our goal is to one day build systems that challenge the natural living systems in the world,” says Professor Bishakh Bhattacharya, of the Smart Materials, Structures and Systems (SMSS) lab at the institute.

Also read: A tiny beetle-inspired robot for big tasks & how ancient meteorites delivered potassium to Earth

Robotic arm that ‘reads’ brainwaves

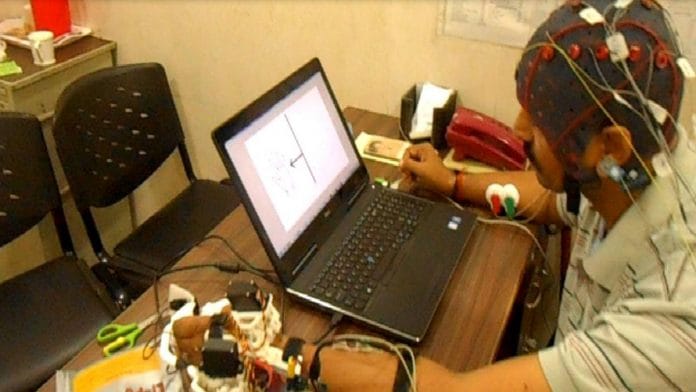

At the Centre for Mechatronics, Dutta’s sights are set firmly on the future. He is most excited to talk about his team’s latest work — a Brain Computer Interface (BCI) with a 3D-printed robotic arm that can help stroke patients recover from paralysis of their limbs.

He explains that physiotherapy often does not work for stroke patients because recovery from stroke paralysis requires a person to actually think hard about moving their limbs — hard enough that the brain is coaxed into rebuilding the wiring that allowed it to move before the stroke.

“In stroke patients, there is nothing wrong with their hands. The nerves and the muscles are all intact. Physiotherapies are very passive — the doctor may be helping the patient move their hands, but there is no way to ensure that the patient is actually focusing on the movement,” Dutta explains.

The team’s BCI — a cap fitted with electrodes — can “read” a person’s brainwave and translate it to action in the robotic arm, in which the patient’s hand is placed.

When the person thinks about moving their arm, the robotic arm moves their fingers. Repeatedly exercising with the device eventually leads the brain to form new connections, restoring its ability to control arm movements.

The team carried out successful trials with four patients in India and the UK, and they are now planning to carry out larger trials.

Game-changing crawlers

Sitting in front of shelves stacked with books from floor to ceiling, Professor Bishakh Bhattacharya runs the Smart Materials, Structures and Systems (SMSS) lab at IIT-Kanpur.

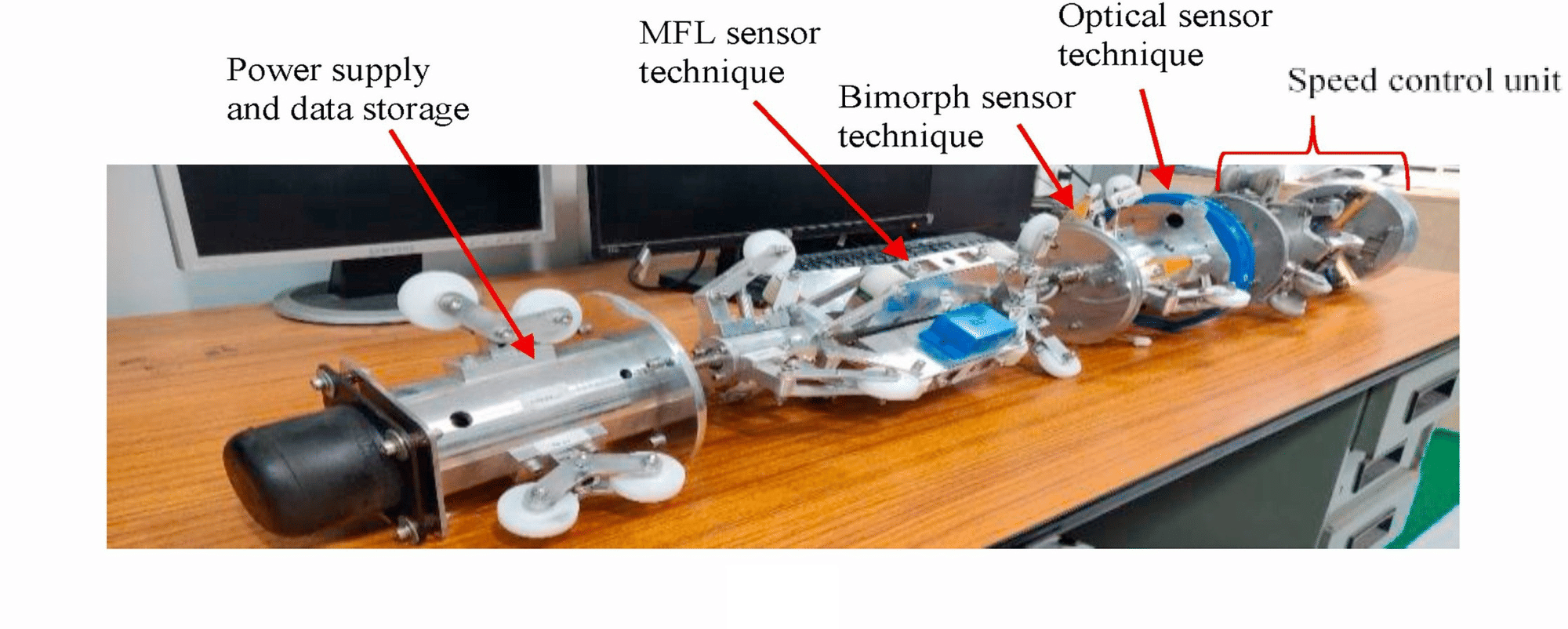

Among their most recent patented technology is a robot that can crawl through gas pipelines to check for leaks and damages.

Built in collaboration with government-run gas company GAIL, the Pipeline Health Monitoring Robot is equipped with optical and magnetic sensors that check for damages in the pipeline.

According to Nayan Jyoti Baishya, who was part of the team that developed the robot, India has over 70,000 kilometres of gas pipelines.

“These pipelines need to be inspected every six months, and we do not have any existing technology to inspect them. We currently outsource this to German and Canadian companies, which charge exorbitant amounts for it,” he says.

“Also, when these inspections are done, they have to block the entire pipeline for it,” he adds.

The Pipeline Health Monitoring Robot, which can run even when the natural gas is flowing, is also the beginning of another story that the lab is writing.

“Using the same scientific principles used to build this robot, we are now working on the idea of a coal hyperloop — a robot that could carry cargo of coal from mines to power stations using continuous underground tunnels,” Bhattacharya says.

While several robots — including a four-legged system that can help farmers monitor crops for pesticides and a medical robot that can assist in surgeries — are under development at the SMSS lab, Bhattacharya’s goal is to solve bigger, more fundamental problems that currently plague the automation industry.

He explains that there are three aspects to building an intelligent system — the material or sensors capable of taking information from the systems around them; the actuators or structures that allow the system to work, and finally the processor that brings “intelligence” to the system.

The SMSS lab works on each of these three aspects.

For example, the lab has developed alloy-based artificial muscles for a robotic arm that can be used to help people with amputated limbs. The advancement does away with the need for heavy, noisy motors in robotic arms and can also have applications for space robotics.

Bhattacharya explains that the processors in use today are primitive in terms of what we see in the natural world. “Unlike the current artificial systems, biological systems do not need thousands of data points to learn simple things. If the processor finds itself facing a novel situation, it will not be able to work,” he points out.

“Biological systems are inherently more perceptive,” he says.

“What we are doing currently is that we are transferring our knowledge to the computers. In a way they are just projections of how we see the world. But intelligence systems can be designed to sense more,” he adds.

According to Bhattacharya, an ideal intelligent system would sense things that humans do not — like seeing in the infrared and ultraviolet range of light, or hearing beyond the human decibel range — and use those inputs to create its own perception.

“That would be a truly intelligent system,” he says.

Beyond pushing the limits of robotics, some IIT-Kanpur researchers are also pushing for better alternatives to some government policies.

Methanol for fuel, fighting the QR code

The Indian government has set a target of 20 per cent ethanol blending in petrol by 2025-2026. However, Avinash Kumar Agarwal, who leads the Engine Research Laboratory at IIT-Kanpur, has taken things a step further with his research on methanol.

Agarwal’s team has been able to tweak the engines of commercial Indian bikes such that they can be shifted from petroleum-based to methanol.

Methanol is a liquid alcohol fuel that can be derived from biomass, such as agricultural waste.

Methanol was used in the 1990s in the US as fuel, but is no longer in use as it has lower energy density, Agarwal says.

“Moreover, there was a misconception that the gas is toxic, but that is true of any fuel. Methanol can cause blindness or death if ingested,” he points out.

According to Agarwal, the use of methanol can reduce the carbon footprint and also lower the cost of fuel significantly.

“Currently, while we are mixing ethanol with fuel, the cost of the fuel has not decreased. The government is blending ethanol with petrol, but the consumer pays the price of petrol,” he says.

Agarwal is working closely with the NITI Aayog towards realising its ‘Methanol Economy’ programme. The initiative is aimed at reducing India’s oil import bill, greenhouse gas (GHG) emissions, and converting coal reserves and municipal solid waste into methanol.

Meanwhile, for Deepak Gupta, a professor of materials science and engineering, the fight is against the now ubiquitous QR codes.

Gupta passionately disagrees with the government’s move to encourage the use of QR codes as a means to secure the quality of medicines and other consumer goods.

“How is a QR code secure? You can simply copy the code and stick it on a counterfeit product — the scan will still show you all the correct information. Anyone can generate a QR code. A truly secure code would be something that no one can replicate with any technology,” says Gupta.

“We were concerned about any kind of forgery in India. Roughly about 20 per cent of products in India — across sectors — are counterfeit,” he adds.

Gupta has created a new security tag that generates a new pattern each time. He drew inspiration from a natural phenomenon, he says: how patterns form when the land surface cracks on becoming too dry.

“Just like our fingerprints, nothing nature makes is identical. Nature always produces variations,” he adds.

Gupta’s method uses a regular ink jet printer to deposit a thin layer of ink on a small patch of paper. When the ink dries, it forms a unique pattern each time, which cannot be replicated.

The layer of ink adds a third layer to the code. An app, designed to read these codes, can also detect whether the pattern it is reading is the real 3D tag, or just a photocopy of it.

“The key to this kind of a security tag is that if the manufacturer is asked to make another copy of it, he should not be able to make it again.”

Keeping time

At IIT Kanpur’s National Centre for Flexible Electronics, a smartwatch for the visually impaired is in the works.

Siddhartha Panda, coordinator of the centre, along with his team has created the device. The team worked with an NGO for years — understanding the needs of a visually-impaired person — before designing the watch.

“Usually, visually-impaired people use an analogue watch with a glass cover that can open. They touch the hands of the watch to read the time. However, the constant touching means that these watches are more prone to wear and tear,” says Panda.

“More recently, there have digital watches with talk-back features. These read out the time, but compromise a person’s privacy,” he explains.

Panda’s team has, therefore, developed a watch that uses tactile feedback in the form of vibrations for a person to read the time.

Just like a regular analogue watch, the TacVibes has 12 markers placed along its circumference. The watch has no moving hour or minute hand. Instead, touching the right markers generates small vibration pulses.

For example, if the time is 2 o’clock, a user will feel a long vibration when they put their finger on the marker for 12, and a short vibration on placing their finger on 2.

Not just that, the smartwatch can also be used to “read” the heart rate, blood oxygen level, etc, using a combination of the vibrations felt on the dial.

The team is now working on commercialising the watch.

The success of IIT Kanpur’s Ventilator Project — which saw the institute develop a ventilator in just three months during the Covid pandemic — has provided a fresh spurt of motivation to the institute to venture into the field of med-tech.

J. Ramkumar heads the MedTech lab of IIT Kanpur and is helping to take a lot of relevant technologies being developed in the institute to the industry.

Working closely with doctors to understand the needs of the field, the MedTech lab is working on technologies such as optical probe for gynaecological testing, portable medical oxygen concentrator for ambulances, and a device for posture correction, among other things.

Off the record, senior researchers say that each of these inventions is driven by the need to solve several problems of society, but there are other pay-offs too.

Some of these technologies, if successful, can turn the founders into millionaires. Most of them come from hardworking, middle-class backgrounds. If their work becomes successful, they could be suddenly sitting on shares worth crores, they said.

(Edited by Nida Fatima Siddiqui)

Also read: At IIT Kanpur, engineers are working on an artificial heart that’s affordable & built to last