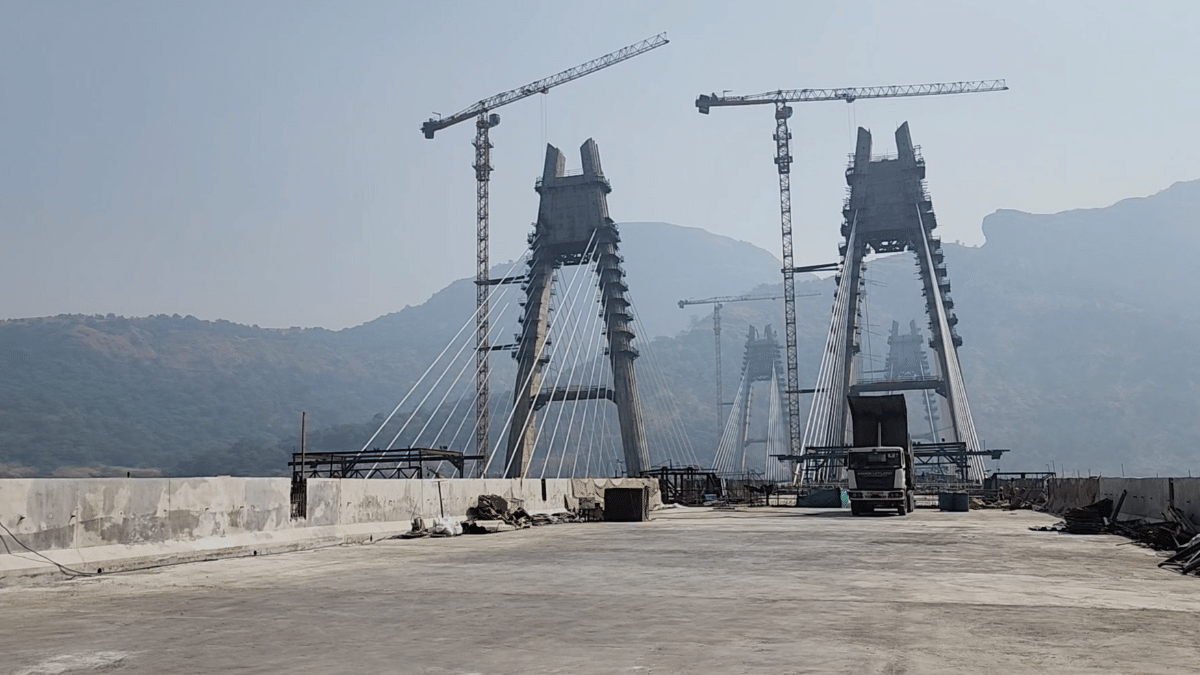

Mumbai/Lonavala: Standing at a height of 182 metres from the ground—the equivalent of a 60-storey building—the cable-stayed bridge in a deep valley on the Mumbai-Pune expressway is an engineering marvel.

Hanging from safety harnesses in the valley, hundreds of workers have been busy for years, building the bridge in the green Sahyadri mountains, come rain or shine, under conditions almost resembling an adventure sport. One small mistake in this case could be fatal.

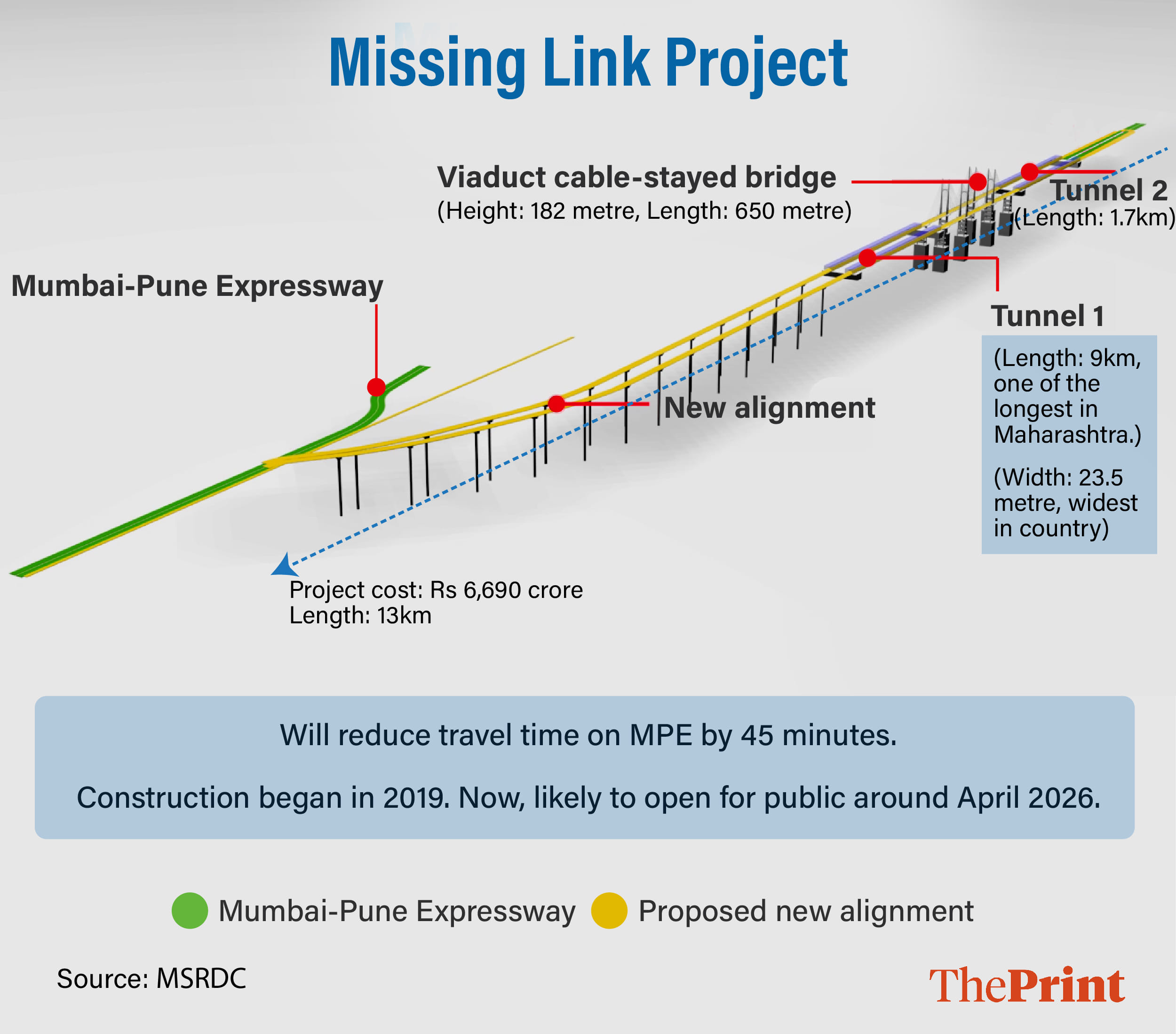

Now nearly complete, the tallest cable-stayed bridge in Maharashtra is a critical part of the Rs 6,690 crore Missing Link project on the Mumbai-Pune expressway, which will cut travel time between the two cities by up to 45 minutes.

“This was very challenging work, and so was taking labourers there to such a height. But our team worked relentlessly to achieve this task, and we will be ready to open the project to the public very soon,” Rajesh Patil, joint managing director of Maharashtra State Road Development Corporation (MSRDC), the nodal agency executing the project, told ThePrint.

After multiple challenges, ranging from the pandemic shutdown and labour shortage, to heavy monsoons, work on the 650 metre-long bridge is 95 percent complete, with the rest set to be wrapped up in two or three months, according to an engineer involved with the project.

And with that, the Missing Link project, for which construction began in 2019, will be opened for public use around April 2026.

Once the Navi Mumbai airport is ready for take-off and the Missing Link operational, travellers from Pune will no longer face long traffic jams in the ghat section.

Also Read: How Mumbai-Nagpur Samruddhi e-way took shape with Fadnavis & Shinde taking turns in driver’s seat

The Missing Link

The Mumbai-Pune Expressway, the first expressway in the country, was built more than two decades ago to cut travel time between the financial capital and the second-largest city in the state.

At that time, a proposal had been made to build the 13 km-long Missing Link as an alternative to the ghat on the expressway, but it was left on the drawing board, said the engineer quoted above. “But when traffic on the expressway started growing and an alternative was being looked at, that is when we went back to this file, which is now called the missing link.”

MSRDC, which also built the Bandra-Worli Sealink in 2009 and the original Mumbai-Pune expressway, was tasked to execute this project.

The Sahyadri ghat section on the expressway is 19 km long with winding roads and steep gradients, which take a lot of time to cross because of the movement of heavy vehicles and massive traffic jams.

Sometimes, the jams can be 5 km long and can more than double the travel time between the cities. The steep gradient has also caused accidents on the expressway.

“This was very challenging work, & so was taking labourers there to such a height. But our team worked relentlessly to achieve this task, & we will be ready to open project for public very soon,” Rajesh Patil, joint managing director, MSRDC.

However, this commute is expected to become much easier with the Missing Link, which begins from the Khalapur exit on the Mumbai end and goes all the way up to the Lonavala exit at the Pune end. It includes two bridges, including the cable-stayed bridge, and two tunnels, along with two viaducts.

MSRDC expects travel time on the expressway to be cut by at least 30 to 45 minutes because of the Missing Link as commuters can bypass the entire ghat section. It is an eight-lane project, with four lanes on each carriageway.

Maharashtra’s tallest cable-stayed bridge

But building the cable-stayed bridge hasn’t been simple. For one, to get to the cable-stayed bridge from Mumbai, a 1.7 km tunnel has to be crossed.

Before starting construction, a temporary access road was constructed from a village about 8 km away to transport trucks and materials.

“As we started building this road, that is when we found the location. Otherwise, building this bridge in the forest was impossible without any approach,” said the engineer. “Now we come via a tunnel so it looks easy, but the planning and designing phase of this bridge itself took a year or two as the forest road was not straight.”

Before construction, MSRDC built a prototype which underwent a wind tunnel test to see how it would respond to specific wind speeds, loads, and different climatic conditions. “We had to test it to make sure it would withstand earthquakes, wind forces, cyclones, etc., and this prototype was brought in from Denmark,” said MSRDC joint managing director Patil.

Since the bridge is connected to the tunnel, where there is no wind, engineers designed wind screens to prevent cars from toppling. The structure has 240 cables, of which 140 cables are complete.

The tunnels

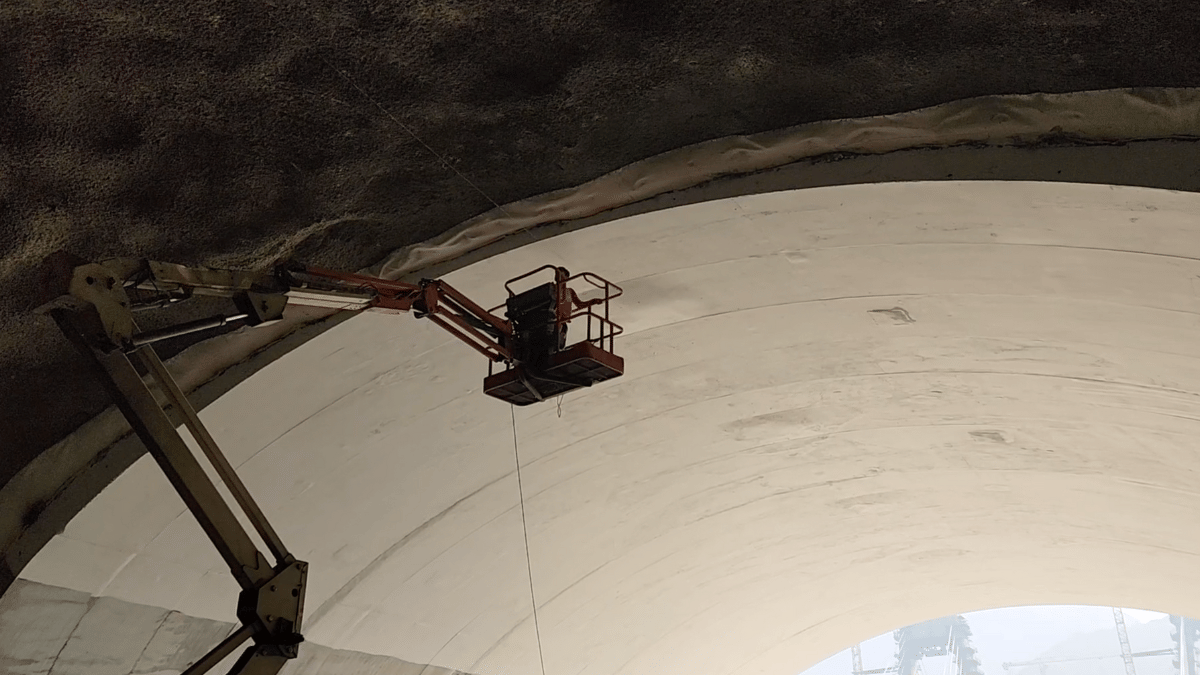

The Missing Link project comprises two tunnels—one 1.7 km long and the other 9 km. The latter, at 23.5 metres wide, will be one of the longest tunnels in the state and the widest in the country, according to MSRDC.

The tunnel is equipped with a high-pressure water mist system, which will deploy in case of a fire. It also has linear heat detection (LHD), which activates the mist system within seconds when temperatures reach 60 degrees Celsius.

“What this mist system will do is create a bubble to control the fire within the small confined area and stop it from spreading across a wider area,” the project engineer in charge of tunnels told ThePrint.

Risks and challenges

One of the biggest challenges was the slowdown during the COVID pandemic, when construction had almost come to a halt.

The cable-stayed bridge’s wires and cables were imported from Malaysia and testing was done in Taiwan, which was shut for most of the time during the pandemic.

“Though we were open, they were closed and when they opened after the pandemic, there was a lot of backlog, which added to the delay,” the engineer said.

“Whenever wind crossed 40kmph, we had to stop work as cranes & towers to take material up and down could not be operated. And this year, monsoon was particularly heavy,” says a project manager

A project manager working on the bridge told ThePrint that the project also faced many practical challenges.

Heavy monsoon rains in the ghat section and thick clouds cover over the mountains made construction difficult.

“Whenever the wind crossed 40 km per hour, we had to stop work as the cranes and towers to take material up and down could not be operated. And this year, the monsoon was particularly heavy and continuous,” the manager said.

The engineer quoted above also spoke about the difficulty of finding labour for such specialised work. Since such projects are infrequent, trained labour leaves after a project is completed. “People from that category find different work in periods where we don’t work on such skilled projects. They don’t mind going into real estate or driving. So, when we need them, they are not available,” he said.

He added that training new people takes time and safety is an important aspect. “This requires a bigger learning curve as labourers frequently go in different directions,” he said.

Besides, the project manager noted, any accident can trigger fear among workers who then would not want to be involved in such a project as panic spreads within the community.

As a result of all these challenges, the original opening date of the tunnel was pushed back from August to December, and now to April.

“With the completion of this project, the ghat section will not come to your notice as the road is straight here. The ghat will be omitted. This will also reduce accidents on the expressway,” said Patil.

(Edited by Sugita Katyal)